- Fundamentals of design

- Design of joints, levers and offset links

- Design of shafts, keys and couplings

- Design of power screws

- Design of springs

- Design of bolted and welded joints

- Selection of anti-friction bearings and gears

Fundamentals of machine design

1 During a tensile loading, the length of a steel rod is changed by 2 mm. If the original length of the rod has been 20 mm, what is the amount of strain induced- (A) 0.1

- (B) 2

- (C) 0.9

- (D) 0.22

2 Stress on components is expressed in ….

- (A) N/mm²

- (B) kN/m²

- (C) Pascal

- (D) All of the above

3 Shear forces are —— forces.

- (A) Aligned.

- (B) Unaligned

- (C) Perpendicular

- (D) Parallel

4 The components having length in —— are usually Buckle.

- (A) X- direction

- (B) Y direction

- (C) Z- direction

- (D) X-Y direction

5 Flexure is also known as —–

- (A) Distortion

- (B) Failure

- (C) Bending

- (D) Twisting

6 Cyclic loads below significant load causes

- (A) Bending

- (B) Fatigue

- (C) Wrapping

- (D) Compression

7 Tensile stresses are applied —– to applied tensile force

- (A) Parallel

- (B) Perpendicular

- (C) cross-sectional

- (D) In same direction

8 Compressive forces are

- (A) Towards the point

- (B) Opposite to point

- (C) Both

- (D) Can’t say

9 Strength of material is maximum in

- (A) Tension

- (B) Compression

- (C) Twisting

- (D) Any of above

10 Stressed parts are always kept in tension.

- (A) TRUE

- (B) FALSE

11 While designing a forging, the profile is selected such that the fibrous lines are parallel to the tensile forces and perpendicular to shear forces.

- (A) TRUE

- (B) FALSE

12 Which of the following is not a reason to design and redesign a product?

- (A) Optimum design

- (B) Innovation

- (C) Appearance

- (D) None of the above

13 In design process, which process is followed after selecting the material?

- (A) Selecting factor of safety

- (B) Synthesis

- (C) Analysis of forces

- (D) Determining mode of failure

14 Which of the following is not a reason to design and redesign a product?

- (A) Optimum design

- (B) Innovation

- (C) Appearance

- (D) None of these

15 The following standard(s) is (are) used in Mechanical engineering design.

- (A) Standards for materials

- (B) Standard for testing of products

- (C) Standards for Fits, Tolerances and surface finish of component

- (D) All of the above

16 The following design process is also known as ‘over the wall’ process

- (A) Sequential Design process

- (B) Concurrent Engineering

- (C) Both A and B

- (D) None of the above

17 The elongation of a bar is 0.5 mm, when a tensile stress of 200 N/mm2 acts on it. Determine original length of a bar if modulus of elasticity is 150 x 103.

- (A) 375.93 mm

- (B) 300 mm

- (C) 360 mm

- (D) None of the above

18 Deformation per unit length is called as ________

- (A) strain

- (B) stress

- (C) modulus of elasticity

- (D) none of the above

19 In design process, which process is followed after selecting the material?

- (A) Selecting factor of safety

- (B) Synthesis

- (C) Analysis of forces

- (D) Determining mode of failure.

20 Which of the following materials do not have a well-defined yield point?

- (A) Heat treated steel

- (B) Concrete

- (C) Carbon fiber

- (D) All of the above

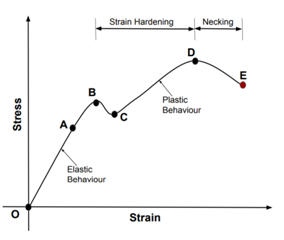

21 In stress-strain diagram, up to proportional limit ______

- (A) stress is inversely proportional to strain

- (B) force is directly proportional to displacement

- (C) stress is directly proportional to strain

- (D) strain is directly proportional to stress

22 Factor of safety is the ratio of _________

- (A) working stress and ultimate strength

- (B) yield strength and endurance strength

- (C) ultimate strength and yield strength

- (D) yield strength and working stress

23 The ratio of endurance strength and allowable stress is used to determine FOS for _____

- (A) fatigue loading

- (B) static loading of brittle materials

- (C) static loading of ductile materials

- (D) all of the above

24 Which of the following is the numerator of factor safety formula?

- (A) Working stress

- (B) Shear stress

- (C) Tensile stress

- (D) Ultimate Stress

25 Which of the following can be the factor of safety for a dead load?

- (A) 6

- (B) 2

- (C) 4

- (D) 7

26 Which of the following can be the factor of safety for shock loading?

- (A) 11

- (B) 13

- (C) 4

- (D) 7

27 Factor of safety is used to find out the reliability of the design.

- (A) TRUE

- (B) FALSE

28 What can understand by the factor of safety equal to one?

- (A) It means that the structure will fail under load

- (B) It means that the structure will only support the actual load

- (C) it means that the structure will support more than the actual load

- (D) There is no relation between factor safety and load application

29 For which of the following design factor of safety the design will work properly?

- (A) 0.1

- (B) 1

- (C) 2

- (D) 0.9

30 What is a safe factor of failure for a component which on failure can result in financial loss or serious injury?

- (A) 1

- (B) 2

- (C) 3

- (D) 4

31 Design factor for most aircraft structures is 2.

- (A) TRUE

- (B) FALSE

32 What is the factor of safety under suddenly applied load?

- (A) 2 and 4

- (B) 4 and 8

- (C) 8 and 16

- (D) None

33 Safety factor in case of a ductile material is

- (A) Real stress/unit stress

- (B) Ultimate stress/maximum stress

- (C) Yield stress/ allowable stress

- (D) None

34 Effect of higher factor of safety on cost of the material?

- (A) Increases

- (B) Decreases

- (C) No change

- (D) None

35 The factor of safety for a ductile material

- (A) σyp/σallow

- (B) (b)σult/σallow

- (C) σult/σyp

36 Factor of safety is the ratio of —–

- (A) allowable stress to critical stress

- (B) critical stress to allowable stress

- (C) normal stress to shear stress

- (D) shear stress to normal stress

37 The factor of safety for—–

- (A) steel and concrete are same

- (B) steel is lower than that for concrete

- (C) steel is higher than that for concrete

- (D) none of the above

38 Design is concerned with——

- (A) Selection of material

- (B) Shape and size

- (C) Arrangements of elements

- (D) All of the above.

39 Is analysis of forces important in designing a machine element?

- (A) Yes

- (B) No

- (C) May be

- (D) Can’t say

40 In which of the following step we can change the size of member.

- (A) Detailed drawing

- (B) Modification

- (C) Both A and B

- (D) none of the above

41 Which of the following is not step of machine design?

- (A) Recognition of need

- (B) Mechanism

- (C) Analysis of forces

- (D) Safety of operation

42 To avoid failure which of the following is important.

- (A) Reliability

- (B) Wear resistance

- (C) Strength

- (D) None of the above

43 Need =>Mechanism =>Analysis of forces =>———=> Design of element.

- (A) Modification

- (B) Production

- (C) Quality checking

- (D) Material selection

44 Is quality checking part of machine designing?

- (A) Yes

- (B) No

- (C) May be

- (D) Can’t say

45 To selection of material——.

- (A) Designer should have a deep knowledge about properties of material.

- (B) Knowledge about properties is not important.

- (C) Both A and B can be done.

- (D) None of the above

46 What will happened if standard parts are used?

- (A) Overall cost reduces

- (B) Develops machine work effectively

- (C) Both A and B

- (D) None of the above

47 Which of the following parameters can be obtained by tension test of a standard specimen?

- (A) Proportional limit

- (B) Yield strength

- (C) Percentage reduction in area

- (D) All of the above

48 Yield strength is defined as the maximum stress at which a marked increases in elongation occurs without increases in

- (A) Load

- (B) Strength

- (C) Toughness

- (D) Hardness

49 Which of the following measuring the stiffness?

- (A) Modulus of elasticity

- (B) Modulus of plasticity

- (C) Resilience

- (D) Toughness

50 Modulus of resilience is defined as

- (A) Strain energy per unit volume

- (B) Strain energy per unit area

- (C) Independent of strain energy

- (D) None of the above

51 Malleability increases with temperature while ductility decreases with the temperature

- (A) TRUE

- (B) FALSE

52 Calculate the diameter of pin from shear consideration with maximum shear stress allowed is 40kN/mm² and an axial tensile force of 50kN is acting on the rod.

- (A) 40

- (B) 50

- (C) 60

- (D) 70

53 For an elliptical hole on a flat plate, if width of the hole in direction of the load decrease, Stress Concentration Factor will be

- (A) Increased

- (B) Decreased

- (C) Remains constant

- (D) Can’t be determined. Varies from material to material

54 In which of the following case stress concentration factor is ignored?

- (A) Ductile material under static load

- (B) Ductile material under fluctuating load

- (C) Brittle material under static load

- (D) Brittle material under fluctuating load

55 Use of multiple notches in a V shaped flat plate will be

- (A) Reduce the stress concentration

- (B) Increase the stress concentration

- (C) No effect

- (D) Cannot be determined

56 Which of the following reduces the stress concentration?

- (A) Use of multiple notches

- (B) Drilling additional holes

- (C) Removal of undesired material

- (D) Each of the mentioned

57 Which of the following is measure of stiffness?

- (A) Modulus of elasticity

- (B) Modulus of plasticity

- (C) Resilience

- (D) Toughness

58 irregularities present in the component and no changes of the cross section.

- (A) TRUE

- (B) FALSE

59 Stress Concentration Factor is the ratio of nominal stress obtained by elementary equations for minimum cross-section and highest value of actual stress near discontinuity.

- (A) TRUE

- (B) FALSE

60 If a flat plate with a circular hole is subjected to tensile force, then its theoretical stress concentration factor is?

- (A) 2

- (B) 3

- (C) 4

- (D) 1

61 For an elliptical hole on a flat plate, if width of the hole in direction of the load decrease, Stress Concentration Factor will——

- (A) Increase

- (B) Decrease

- (C) Remains constant

- (D) can’t be determined. Varies from material to material

62 Is it logical to use fluid analogy to understand the phenomenon of stress concentration?

- (A) TRUE

- (B) FALSE

63 Use of multiple notches in a V shaped flat plate will

- (A) Reduce the stress concentration

- (B) Increase the stress concentration

- (C) No effect

- (D) Cannot be determined

64 A flat plate 30mm wide and “t” mm wide is subjected to a tensile force of 5kN. The plate has a circular hole of diameter 15mm with the center coinciding with the diagonal intersection point of the rectangle. If stress concentration factor=2.16, find the thickness of the plate if maximum allowable tensile stress is 80N/mm².

- (A) 8mm

- (B) 9mm

- (C) 10mm

- (D) 12mm

65 The fatigue stress concentration factor is defined as

- (A) The ratio of endurance limit with stress concentration to the endurance limit without stress concentration

- (B) The ratio of endurance limit without stress concentration to the endurance limit with stress concentration

- (C) The product of the endurance limits with and without stress concentration

- (D) All of the above.

66 Stress may be defined as _________

- (A) Force per unit volume

- (B) Force per unit length

- (C) Force per unit area

- (D) None of these

67 The forces acting on the bar as shown in the given figure introduce _________?

- (A) Tensile stress

- (B) Compressive stress

- (C) Shear stress

- (D) None of these

68 The property by which a body returns to its original shape after removal of the force is called __________

- (A) Plasticity

- (B) Elasticity

- (C) Ductility

- (D) Malleability

69 Which law is also called as the elasticity law, which states that stress is proportional to the strain within the elastic limit?

- (A) Bernoulli’s law

- (B) Stress law

- (C) Hooke’s law

- (D) Poisson’s law

70 A member which does not regain its original shape after removal of the load producing deformation is said __________

- (A) Plastic

- (B) Elastic

- (C) Rigid

- (D) None of the mentioned

71 As the elastic limit reaches, tensile strain __________

- (A) Increases more rapidly

- (B) Decreases more rapidly

- (C) Increases in proportion to the stress

- (D) Decreases in proportion to the stress

72 The dimension of strain is?

- (A) LT-2

- (B) N/m2

- (C) N

- (D) Dimensionless

73 Live loads, with time can vary in_________

- (A) Magnitude

- (B) Position

- (C) Neither position nor magnitude

- (D) Position as well as magnitude

74 What is the first step in the ‘General procedure of machine design’?

- (A) Analysis of forces

- (B) Material Selection

- (C) Need or aim

- (D) Detailed drawing

75 Sizes of machine components are decided in which stage of general procedure of machine design?

- (A) Material selection

- (B) Detail drawing

- (C) Design of element

- (D) Analysis of forces

76 Detailed drawings of designed machine elements are needed by workers to machine/fabricate/assemble the machine elements. Is this statement true.

- (A) TRUE

- (B) FALSE

77 When you design a machine element you should make use of standard elements as much as possible?

- (A) TRUE

- (B) FALSE

78 A machine designer should consider the following factors among others

- (A) Workshop facilities

- (B) Selection of materials

- (C) Types of loads and stresses

- (D) All of the above

79 Compressive stress acting on the contact area between two components having no relative motion between them is known as crushing stress

- (A) TRUE

- (B) FALSE

80 At the neutral axis, bending stress is _____

- (A) Minimum

- (B) Maximum

- (C) Zero

- (D) Constant

81 What is the product of force and radius?

- (A) Twisting shear

- (B) Turning shear

- (C) Turning moment

- (D) Tilting moment

82 What is the unit of the Stress and strain

- (A) N/mm2 and mm

- (B) N and mm

- (C) N/mm and mm2

- (D) N/mm2 and No unit

83 Stress is

- (A) External force

- (B) Internal resistive force

- (C) Axial force

- (D) Radial force

84 The stress which acts in a direction perpendicular to the area is called ____________

- (A) Shear stress

- (B) Normal stress

- (C) Thermal stress

- (D) None of the mentioned

85 Which of these are types of normal stresses?

- (A) Tensile and compressive stresses

- (B) Tensile and thermal stresses

- (C) Shear and bending

- (D) Compressive and plane stresses

86 The stress induced in a body, when subjected to two equal and opposite forces which are acting tangentially across the resisting section resulting the shearing of the body across its section is called ____________

- (A) Bending stress

- (B) Compressive stress

- (C) Shear strain

- (D) Shear stress

87 Following are the basic types of stress except

- (A) Tensile stress

- (B) Compressive stress

- (C) Shear stress

- (D) Volumetric stress

88 The deformation per unit length is called

- (A) Strain

- (B) Stress

- (C) Elasticity

- (D) None of these

89 The ability of the material to deform without breaking is called

- (A) Elasticity

- (B) Plasticity

- (C) Creep

- (D) None of these

90 The stress at which extension of a material takes place more quickly as compared to increase in load, is called

- (A) No elastic zone

- (B) Plastic point

- (C) Yield point

- (D) Breaking point

91 A perfectly elastic body

- (A) Can move freely

- (B) Has perfectly smooth surface

- (C) Is not deformed by any external surface

- (D) Recovers its original size and shape when the deforming force is removed.

92 When a section is subjected to two equal and opposite forces tangentially to the section, the stress produced is known as

- (A) Tensile stress

- (B) Lateral stress

- (C) Shear stress

- (D) No stress

93 In the stress strain diagram shown in the figure, what does the letter D represent?

- (A) Upper yield point

- (B) Lower yield point

- (C) Ultimate limit

- (D) Braking point

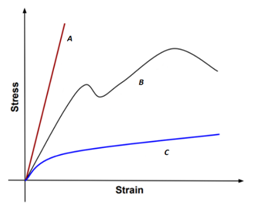

94 Match the materials with the stress-strain curves in the given figure?

- (A) A- Cast iron, B- Plastic, C- Mild steel

- (B) A- Cast iron, B- Mild steel, C- Plastic

- (C) A- Mild steel, B- Cast iron, C- Plastic

- (D) A- Plastic, B- Cast iron, C- Mild steel

95 An example of ductile material is

- (A) Cast iron

- (B) Rubber

- (C) Glass

- (D) Mild steel

96 An example of brittle material

- (A) Cast iron

- (B) Rubber

- (C) Glass

- (D) Mild steel

97 Hooke’s law holds good up to

- (A) Yield point

- (B) Limit of proportionality

- (C) Breaking point

- (D) Elastic limit

98 Strain is defined as the ratio of

- (A) Change in volume to original volume

- (B) Change in length to original length

- (C) Change in cross-sectional are to original cross-sectional area

- (D) Any one of the above

99 It equal and opposite forces applied to a body tend to elongate it, the stress so produced is called

- (A) Internal resistance

- (B) Tensile stress

- (C) Compressive stress

- (D) Working stress

100 A thin mild steel wire is loaded by adding loads in equal increments till it breaks. The extensions noted with increasing loads will behave as under

- (A) Uniform throughout

- (B) Increase uniformly

- (C) First increase and then decrease

- (D) Increase uniformly first and then increase rapidly